Kesalahan format email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

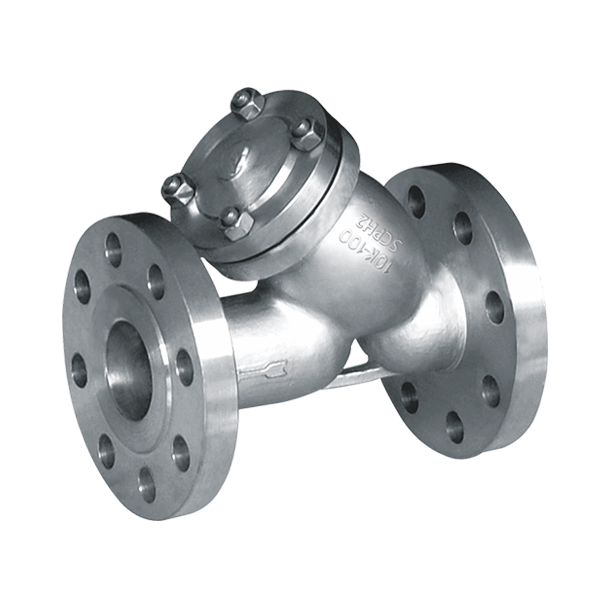

ANSI 150LB Y TYPE STRAINER

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Y Type Strainer, Carbon Steel or Stainless Steel, Flanged Ends.

A device through which a liquid is passed for purification, filtering or separation from solid matter; anything (including a screen or a cloth) used to strain a liquid a perforated screen or openwork (usually at the end of a suction pipe of a pump), used to prevent solid bodies from mixing in a liquid stream or flowline.

Y Type

Carbon Steel or Stainless Steel

Stainless steel screen

Long life service

China Bronze Y Strainer Supplier Dervos Offers Bronze Y Strainer, ANSI B16.34, 6 Inch, Class 150, Raised Face End, Working Temperature -29℃~+400℃.

Key Specifications / Features

Strainer description:

Design standard: ANSI B16.34.

Body material: Bronze.

Nominal diameter: 6 Inch.

Pressure: 150 LB.

End connection: RF.

Face to face: ASME B16.10.

Working temperature: -29℃~+400℃.

Test and inspection: API 598.

Product Range:

Body material: Carbon Steel, Stainless Steel.

Normal diameter: 2"~60" (DN50~DN1500).

End connection: BW, Flanged.

Pressure range: 150 lb~2500 lb (PN16~PN420).

Working temperature: -196℃~+600℃.

Keywords of Bronze Y Strainer, ANSI B16.34, 6 Inch, Class 150, Raised Face

Bronze Y Strainer

Products Related to Bronze Y Strainer, ANSI B16.34, 6 Inch, Class 150, Raised Face

OVERVIEW: The Model YSF is a stainless steel Y strainer (wye strainer) that can be used in applications for steam, water, oil, or gas where protection from foreign matter in a pipeline is required. The YSF1 is 150# class, the YSF2 is 300# class, the YSF3 is 600# class, the YSF5 is 1500# class (RT flanges available), and the YSF6 is 2500# class (RT flanges standard).

They have flanges that are drilled in accordance with ASME B16.1, and perforated 304 stainless steel screens are welded along the seam for maximum strength. If the media is not specified, screens for liquid will be supplied.

Convenient gauge taps are furnished with a plug on both the inlet and outlet sides. These taps allow for easy installation of pressure gauges to monitor differential pressure to determine when screen cleaning is needed.

With its large body and sizable straining element, the YSF models provide excellent open area ratios that are typically two-and-a -half times larger than the corresponding pipeline, minimizing the pressure drop.

These stainless steel units are epoxy painted to help resist rust and corrosion. Stayflow also offers epoxy coatings as an option. They are also are available with different cover options, including swing, clamp, and hinge type covers.